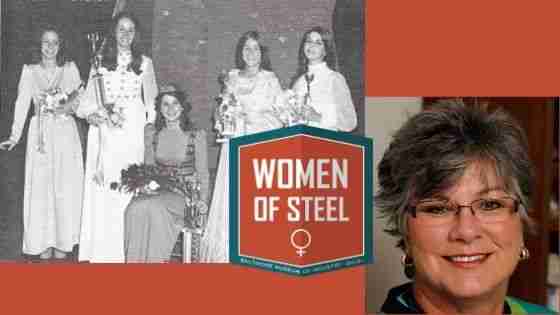

“Women of Steel,” an outdoor exhibition currently on display at the Baltimore Museum of Industry, examines the experiences of women who worked at Sparrows Point. This blog series hopes to highlight more voices of women steelworkers. Today, we hear from Sandy Adams Doyle as she recalls her days as a millwright’s helper at Sparrows Point.

Back in 1978, I took the tool test at Bethlehem Steel and passed. I remember a huge burst of enthusiasm in the HR office, with people shouting, “We got a girl who passed the tool test!” Soon I would become a millwright’s helper – a very prestigious job at the time, especially for a woman. I then had to tell my dad about it. My dad had worked at The Point for 30+ years and had retired from the tin mill, as an electrical foreman. Me? I was a frustrated college grad who had worked in professional sales. Don’t get me wrong. I made good money and was successful, but it just wasn’t fulfilling. I wanted to try something totally different; more satisfying. And because I had always helped my dad with jobs around the house, I was very familiar with tools. So why not see if there was something I could do at Bethlehem Steel.

My dad’s reaction was pretty dismal. “I didn’t put you through college to work down there. Get dressed in old clothes because you are going to get dirty. See how you like it.” And with that, he made me change the oil in the car, grease a couple of fittings and crawl around under the house. I was dirty but undeterred.

When my first day on the job rolled around, my dad gave me his metal lunch box and warned me not to let any of those guys send me for a 3-way valve without telling me the size or a ‘sky hook’. To my surprise, inside the lunch box was a book titled The Encyclopedia of Tools.

I worked in the coke ovens area – a really DIRTY and HOT place (especially in August, which is when I started). The team I worked with was all men, some of whom had been there for many years. They begrudgingly accepted me but made me prove myself. Every day there was something new to ‘fix’ or work on. I became familiar with their processes and admired their ingenuity. At lunch, I often referred to my tool book, hiding it under the table so that no one would notice. But one day, someone said “What are you reading Sandy?” As I replied “nothing,” someone grabbed my book. “Looky, Sandy is reading a tool book!” I embarrassingly retrieved my book and stowed it away in my lunch box. About a week later, we had to repair a hydraulic line on a coal pusher. Someone checked out the tube bender from the tool shop but no one knew how to put it together. Of course, someone yelled: “Sandy, go get your tool book!”

My experience at Bethlehem Steel was remarkable. I had total respect for the men I worked with. Their knowhow is what kept the place running and their ingenuity solved problems that could have not only hindered production but stopped it. They accepted me and gave me confidence to do the same thing. Had a layoff not ended my job prematurely, I probably would have had a career there. It was the most exciting and fulfilling job I’ve ever had.

Have a story of your own to share? Learn more here.