And it happened right here in Baltimore

The recent donation of personal papers and memorabilia from J. Carroll Tulloss, a senior development engineer at Western Electric Baltimore Works, inspired BMI Archives volunteer Ken Jones to dig into the engineer’s history.

What he discovered was that the innovations Tulloss pioneered at Western Electric helped build the telecommunication infrastructure of the United States and the world. And it happened right here in Baltimore.

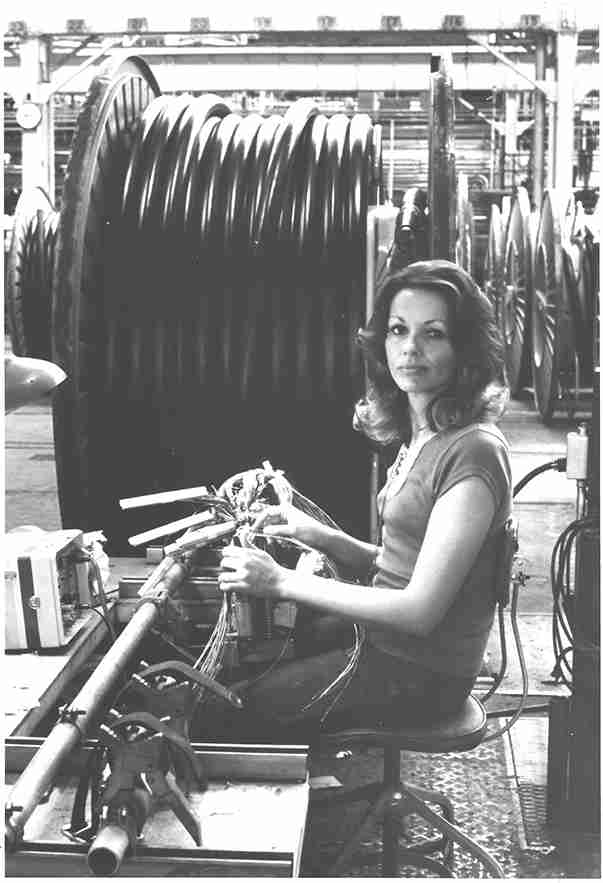

In 1930, a 168-acre site on Colgate Creek, once the home of Riverview Amusement Park, became the site of Western Electric Baltimore Works’ sprawling 2.5-millionsquare-foot facility. The Baltimore Works was the manufacturing arm of American Telephone and Telegraph (AT&T). For more than 50 years, it produced the telephone cable, insulated wire, telephone cords, and other telecommunications apparatus that helped transform how voice and data are transmitted.

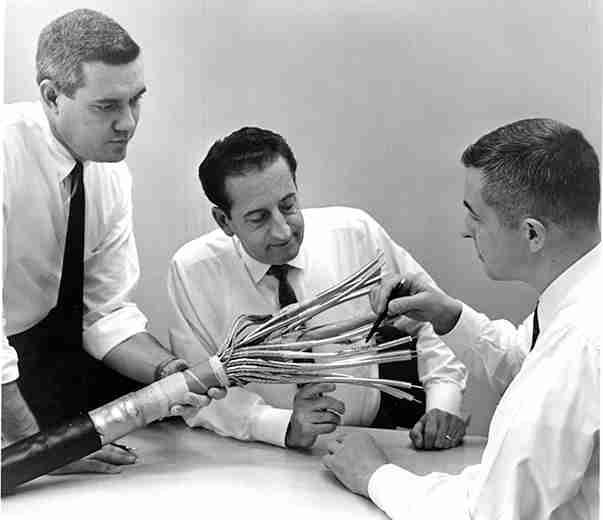

J. Carroll Tulloss holding the 22-tube cable he developed for Western Electric Baltimore Works.

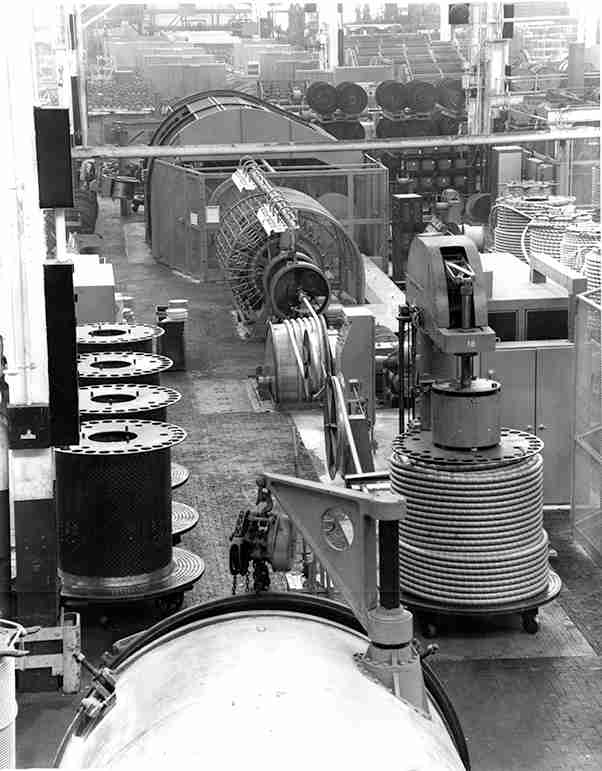

Manufacturing multi-strand coax cable

A significant jump in the capacity of the “L” carrier system came in the late 1950s, when Bell Labs asked if a 12-strand coax cable could be made at the Baltimore Works. The Baltimore manufacturer accepted the challenge. But a new machine would need to be designed and built to make it possible. The task of developing the mechanical and electrical specifi cations for the machine fell to project engineer J. Carroll Tulloss. The machine was installed in the fall of 1960 and began cranking out nine miles of coax cable daily for the Bell System. Ten years later, Bell Labs developed the most sophisticated of its coax cables, the Coax-22. This 22-strand coax cable had a total capacity of 132,000 telephone calls. Once again, Tulloss led the development of the specifications for the new machines required to manufacture this cable.

A victim of changing technology

The 22-strand coax cable that Tulloss helped engineer was the culmination of the “L” carrier system. In the late 1970s, Corning Glass created the first fiber optic cable, which had 125,000 times the capacity of copper wire. Decreased demand for copper cable due to technological and market forces led to the closing of the Western Electric Baltimore Works on February 28, 1986. The industrial powerhouse had once employed 6,200 people. On the day it closed, just 65 clocked in.

Cable Machine

Transcontinental communications

Baltimore native J. Carroll Tulloss joined Western Electric in 1938, about 60 years after Alexander Graham Bell received a patent for the telephone. In the intervening de- cades, Western Electric won the contract to manufacture Bell’s telephone and AT&T was formed to build and operate a long-distance telephone network. When the two companies merged, Western Electric became the exclusive manufacturer of all components for the company’s network.

Building a transcontinental tele- phone network was one of AT&T’s top priorities. To do so, it needed to figure out a way to overcome signal weakening over long distances. The technological breakthrough came with the development by Dr. Lee DeForest of the audion, a three-element vacuum tube that could send radio waves more effectively and amplify them as well. AT&T purchased the audion patent from DeForest and applied the concept to the development of a high-vacuum tube for amplifying sound in telephone cables. The buildout of the transcontinental network could now move forward.

As demand for more telephone lines and equipment grew in the early decades of the twentieth century, AT&T rose to meet the challenge. The first transcontinental telephone calls were transmitted over four copper wires held up by 130,000 wooden poles. The grow- ing demand for long-distance telephone service required a more efficient way to transmit the signal. The search for a broader bandwidth, higher capacity transmission medium was on.

Western Electric employee splicing cable

It’s all about the cable

In 1929, scientists at Bell Laboratories, AT&T’s research and development subsidiary, invented and patented a high-capacity coaxial cable. By 1936, they had developed a semi-commercial coax cable system with one tube capable of carrying 240 conversations. To manufacture the improved cable, AT&T turned to Western Electric Baltimore Works. Bell Labs continually improved the system.

By 1948, more than 5,000 miles of first-generation coax cable—the “L” carrier system—were in service, providing telephone circuits and television networking facilities up and down the East Coast and west to Chicago and St. Louis. Based on the success of the system, AT&T committed to building out a nationwide coax system for telephone circuits, television networking, and national defense communications. As Bell Labs continued to develop higher capacity coax cable, it looked to the Western Electric Baltimore Works to develop the means to manufacture it.

Carroll Tulloss and two engineers with cable